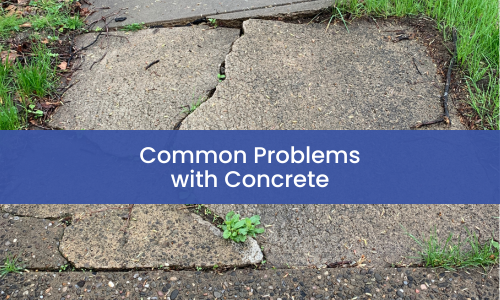

Concrete is the most durable pavement material available to contractors, but if it is not installed or maintained properly, it will eventually develop problems. The most common problems with concrete include:

- Severe cracking

- Crazing, delamination and other surface defects

- Spalling and joint failures

- Heaving

- Base failures

These issues may be severe enough to threaten the concrete’s structural integrity, especially if these problems are not immediately addressed.

Five Common Concrete Problems

Concrete’s durability is unmatched, so when it does develop issues, they are often the result of poor installation or maintenance practices. Here is a closer look at common concrete problems:

-

- Severe cracking – All pavement cracks to an extent as it settles in, and the majority of these cracks are minor and not a threat to the pavement’s stability. However, some cracks may extend through the concrete’s entire depth. Full-depth cracks can emerge anywhere in the concrete. Transverse cracks run perpendicular to the concrete’s centerline. Longitudinal cracks run parallel to the centerline. Both types of cracks may extend through the pavement’s full depth. Concrete can also crack at the corners.

Not all full-depth cracks are a structural concern, but they can accelerate wear to the pavement via water intrusion or additional loading forces. The recommended course of action is to schedule a professional inspection and have the problem assessed.

- Surface defects like crazing – Concrete may develop surface-level problems that, again, are not structural risks, but may affect the pavement’s aesthetics. Crazing is extremely common. Also referred to as map cracking, crazing is a network of fine, hairline cracks that appear in the concrete’s surface shortly after installation. These are usually the result of poor curing practices.

Another common surface defect is delamination, which is when one or more layers inside the concrete separate and peel off the top. This typically occurs when the concrete is not “bled” sufficiently (given time to release air trapped in the pavement).

- Joint issues such as spalling – Joints are potential failure points in concrete and require focused attention during installation and maintenance. When time, wear and weather affect those joints, it can result in spalls, which are chips and chunks of concrete crumbling from these compromised areas. Minor spalling usually won’t threaten the pavement itself, but it exposes the concrete to further wear and damage. Spalls also affect the concrete’s appearance and can contribute to the pavement looking aged. Some can be repaired with patching, but as they point to deeper joint-related issues, full-depth repairs or replacement may be necessary.

- Heaving – Heaving happens when adjacent slabs of concrete are pushed up or sag down relative to each other. Heaving is almost always a weather-related phenomenon, caused by water seeping into the base and then freezing. The resulting expansion of water pushes the slab up and results in serious damage to the pavement.

Heaving is not a major concern along the Gulf Coast, but it is still important for property owners to protect their concrete against water in the event of a hard freeze. If heaving does occur, the only solution is base reinforcement and full concrete slab replacement.

- Base failures – Base failures are the result of poor site preparation techniques, like inadequate soil compaction or grading. If the site is not graded and stabilized sufficiently, the base will shift and subside under the concrete, causing the pavement to collapse and fracture. Because base failures emerge below the pavement, the only way to fully address the problem is to remove any failed patches of concrete, stabilize the base and replace the pavement.

- Severe cracking – All pavement cracks to an extent as it settles in, and the majority of these cracks are minor and not a threat to the pavement’s stability. However, some cracks may extend through the concrete’s entire depth. Full-depth cracks can emerge anywhere in the concrete. Transverse cracks run perpendicular to the concrete’s centerline. Longitudinal cracks run parallel to the centerline. Both types of cracks may extend through the pavement’s full depth. Concrete can also crack at the corners.

What Are Some Common Problems with Reinforced Concrete?

Reinforced concrete displays greater load-bearing capacity as the steel bar inside the concrete complements its compressive strength. However, adding steel to concrete poses additional maintenance concerns, including spalls and cracks emerging from and around the steel reinforcement.

Concrete itself is chemically inert, but once steel is mixed in, corrosion is a potential threat. Corrosion, or rust, will build up around the steel reinforcement if water manages to reach the reinforcement cavity. If it does, the resulting chemical attack will cause the steel to expand in size, placing intense internal pressures on the concrete. If unchecked and severe, this can lead to sudden, major failures in the reinforced pavement.

If you see the signs of corrosion (rust-like discoloration) around your reinforced concrete, or if there is reason to believe that the concrete’s internal structure is exposed to water, it is time to schedule an inspection with a reputable paving contractor.

Common Problems with Concrete Can Be Addressed by an Experienced Pavement Team

Concrete is designed to withstand the elements and intense load-bearing forces. It is designed for durability, but even the best mixed and installed concrete will eventually develop minor issues, like crazing. This is common and is not generally a cause for concern. However, when concrete damage extends through the pavement’s entire depth, it is time to act, and that means partnering with a proven pavement expert to handle the job. An experienced concrete contractor will be able to properly assess, diagnose and repair (or replace) your pavement problems, including deep cracks, fractures, spalls, joint failures or base failures.

- What is the Importance of Asphalt Milling in Houston? - January 15, 2026

- The Hidden Costs of Pavement Cracks: Why Crack Sealing Saves Your Budget - January 9, 2026

- How are Prime Coat and Tack Coat Used During Asphalt Pavement Installation? - December 19, 2025